Turning CO2 into valuables: Carbon2Chem®

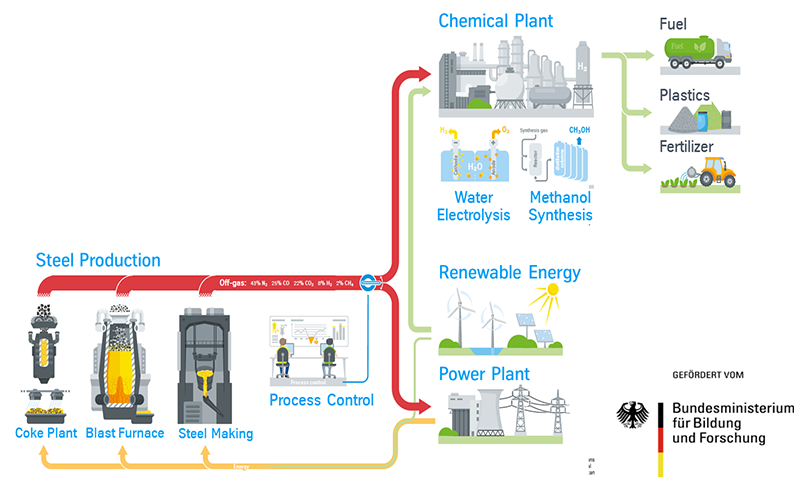

The objective of Carbon2Chem® is to convert process gases from steel production into base chemicals – including the CO2 contained in them –. As a result, the greenhouse gas CO2 would no longer emitted into the atmosphere. And: The energy required for the conversion process is to come from renewable sources.

Carbon2Chem® is characterised by broad-based, cross-industrial cooperation. It will create a new network of steel production, electricity generation and chemical production. 16 partners from the areas of basic and applied research as well as various sectors of industry are involved in the project. thyssenkrupp and the Max Planck Institute for Chemical Energy Conversion have carried out the preparatory planning and scientific work.

“Carbon2Chem® can be an important contribution to climate protection and the transition to renewables,” said Dr. Heinrich Hiesinger, CEO of thyssenkrupp AG.

At present, gases from steel production are burnt off to produce electricity and heat for the production process. As a step change, Carbon2Chem puts the gases at the start of a chemical production chain. This is possible because steel mill gases contain among other things, hydrogen, nitrogen and carbon oxides, the basis for numerous chemical products.

CO2 can be used as a raw material by splitting its molecules. This requires hydrogen, which is in part already present in the steel mill gases. Further hydrogen is to be produced via water electrolysis using renewable energies. The processes in the steel mill will be modified so that part of the process gases are diverted to chemical production when low-cost excess electricity is available from renewable sources.

Carbon2Chem®’s prospects of success are good because the fundamental chemical processes and necessary technologies are largely known. the conversion of process gases into ammonia and urea as precursors for fertilizers is technically, but not yet cost-efficient, possible. This process would use part of the CO2 contained in the steel mill gases. It is also possible to produce methanol from steel mill gases, a process in which the CO2 amounts present could be almost entirely utilised.

This spring a technical centre was built on the premises of thyssenkrupp Steel Europe’s steel mill in Duisburg to test the Carbon2Chem processes on a pilot scale. The centre comprises a plant for water electrolysis using renewable energies. It also contains a plant for cleaning and processing the steel mill gases.